| Sign In | Join Free | My entremaqueros.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My entremaqueros.com |

|

Brand Name : bluesteel

Model Number : bl

Certification : ce

Place of Origin : China

MOQ : 1

Price : negotiable

Payment Terms : T/T or L/C

Supply Ability : 50sets /month

Delivery Time : 45days

Packaging Details : spare parts in wooden box,other plastic film cover

thickness range : 0.3-0.7mm

material stress : 235MPa 345MPa and 550MPa.

roller material : No.45steel

system : PLC control automatic system

a. If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also trai n your workers/technician face to face.

b. Without visiting, we will send you user manual and video to teach you to install and operate.

c. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

1. PLC computer control

2. no noise,no shake

3. hydraulic system,long operating

4. easy operation

5. maintenance-free

Technical data of steel corrgated roll forming machine

| Suitable material | color steel sheet;0.7-1.0mm,1.5mm, 2mm |

| Working speed | about8-25m/min |

| stress | 235MPa,345MPa,550MPa. |

| Power | Main motor power: 12 Kw(Depend on final design) |

| Hydraulic station power: 3Kw(Depend on final design) | |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel, Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 9500KGS |

| Machine’s size | about 18m×1.8m× 1.5m (Depend on final design) |

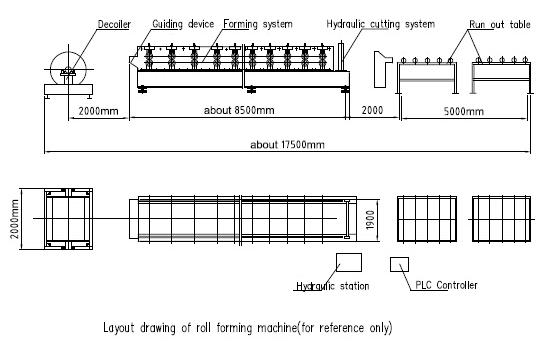

Layout drawing of machine

Our Roll Forming Machine’s advantages

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome .to protect surface shiniing and strong

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.and hardness 60 degree.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine. Rollers are CNC processed to ensure precision performance.

5 .automatic PLC : introduced Mitsubishi PLC with touch screen ,inverter,transformer.

6. powerful driving system: big inch train,or gear box driving system.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

producing process:

Application: downspout, rainspout, rainwater downpipe, water pipe

We can customize the products according to customer ' s requirements

|

|

Tube Roll Former Downpipe Roll Forming Machine With Double Head Decoiler Images |